|

DIY-Welder - Build your own Arc, MIG and TIG welder |

Page hits:  |

Old Boards:

Note: I am no longer building the simplified boards.

I do not have any boards left. So don't ask.

200A Arc, MIG and TIG Welder

|

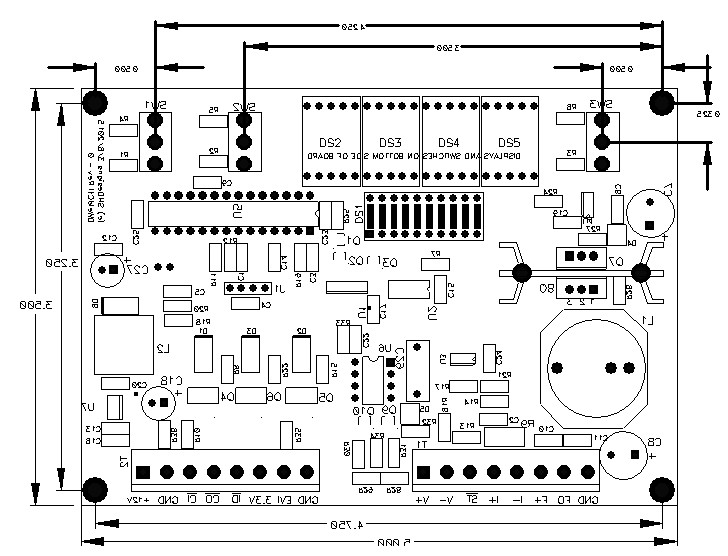

The original, MIG, TIG and Arc (stick) digital board.

Worked well as a test bed.

The original, MIG, TIG and Arc (stick) digital board.

Worked well as a test bed.

|

Update: March 2, 2015 Finally have some progress!

I have been fighting with the options for a new design. The

original digital board was complex and expensive. Some of the

complexities:

- Isolated voltage sense

- Isolated current sense

- Isolated output, up to 200V

- Switching power supply with 3 isolated outputs.

- Lots of analog for real-time control

- 150 parts

- Expensive encoder for input

- MIG, TIG, Stick and battery charger modes.

- Mechanically complex.

- Current sense was hard to calibrate.

It worked, but was never something I wanted to build. Lots

of expensive parts like linear optoisolators. This complexity

was to allow it to be used in 3 configurations:

- DC welder using automotive alternator

- AC/DC TIG and MIG add on for standard engine-driven welders

(I.e a Pipeliner, SA-250)

- Add on for transformer welders like an Airco, Miller DDR/3,

Dialarc and others that use saturation transformers.

The simplified board was just for an alternator. It worked

well but as soon as I started building it, the switches went from

$1.49 to almost $6 each. It was a bit too simplified: it only

drove the field voltage high, was fixed in function and did not

support TIG safely.

Stick (SMAW), TIG and MIG are the goals of the new board. If

all you need is stick welding, the Non-Electronic

Version will be all you need.

One of the problems with the simplified board was no isolation;

everything was referenced to the negative output of the alternator.

DC TIG is electrode negative. So, you connect the positive lead

to the work. That puts the alternator, board and the entire welder

metal at the OCV of the welder, usually 60V. Not a safe situation.

I have been playing with ideas to do this relatively inexpensively.

The first change is to use a modern CPU like a Microchip PIC32.

This will move all the voltage, current and output control from

lots of analog parts to software. That makes it easier to change

and add features like hot start, lift start, engine controls.

Having a built-in display eliminates the need for the user to

add meters or displays.

I have a schematic near done. It is not too bad in complexity

in circuit or mechanically. Still not cheap as I would like, but

reasonable. The features are so far:

- 4-digit LED display with 10 status LED's.

- User input through 3 toggle switches. Up/Down, Display, and

a mode/remote switch. All switches are 3-position (ON/OFF/ON)

momentary.

- Isolated voltage sense - Allows safer TIG.

- Control output up to 8 amps to support dual alternators.

A build option for up to 200V out (engine welders).

- Stick, TIG, MIG and battery charger modes.

- Current sense via the field current - not real accurate but

good enough. My experience with different welders is the current

setting is approximate any way. 120A on one machine acts differently

than 120A on another.

- PIC32 socketed CPU. Allows for software upgrades. I'd like

to be able to download new code but that adds USB or serial interfaces

that would rarely be used and just adds cost.

- Allow saving and loading configurations.

- Support for an engine idle solenoid.

- Lift start TIG, start at minimum current until arc is established.

- Start power output for an external HF start circuit.

- External Contactor output (useful for better MIG startup.)

- Remote voltage/current control.

- Single board maybe 5x3 inches. This would mount to a 4x6

red plexiglass panel. Would hope to have the panels silkscreened

with all the text and labels.

- Screw terminals for connections.

- Option for external board for true current sense (useful

for engine welders.)

Have some time to develop this now; no definite schedule

though. Not sure on the costs yet. First boards would have to

cover prototype boards, and having the panel made and silkscreened.

If anyone knows a place to have the panels cut, drilled and silkscreened

inexpensively; let me know. Feel free to discuss it on the Yahoo

group at the top of the page.

Schematic so far can be

seen here.

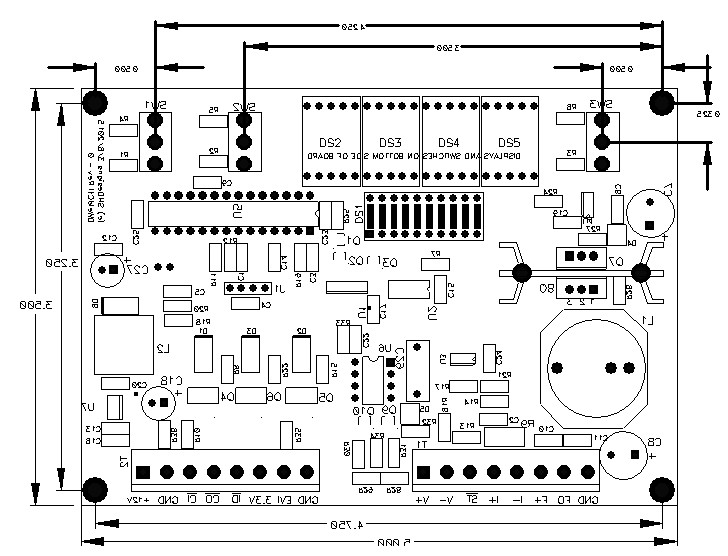

Here is a preliminarey layout. 3.5H x 5W inches

Note: View is from back of board where the displays

and switches are (rest on top side.) So top side parts and text

are mirrored.

Note: View is from back of board where the displays

and switches are (rest on top side.) So top side parts and text

are mirrored.

General info on this site.

You can build a welder with a modified alternator,

a few resistors and some welding cables. Can be powered by a gas

or electric motor. There are several of these floating around

like the "weldernators". They basically work, but have

little output control. They will also likely blow out the rectifier

bridge as there is no protection from the output running away

and no stabilizer for a better arc. These typically run at about

20V; that will work, but hard to maintain an arc.

The idea is to have a generic control board to allow

any power source with current/voltage control to be used for Arc,

MIG and TIG welding. It has a programmable slope and OCV just

like the big welders have. Also it supports both Constant-Voltage

(CV) and Constant-Current (CC) modes so TIG, ARC and MIG can be

done. It can also be used as a fast battery charger.

This can be used for a home-built welder that can be

made relatively inexpensively (second prototype shown above.)

The control board with a suitable motor (gas or electric), an

alternator, belt and pulleys and you will have a very capable

DC arc welder. 10HP electric or 12HP gas should be enough for

DIY use. Add gas and a wire feeder and you will have MIG. Add

a TIG torch and gas solenoid and you can do scratch start TIG.

The board has a manual with all the connections explained. Most

of the work is mechanical.

Scratch-start DC TIG is supported. A HF start is planned

The menu at the top shows the options from a simple arc welder

to a multi-process setup. There are also examples of my two prototype

designs..

Questions or comments, feel free to contact me at

All Web pages, images and text Copyright (c) 2009-2015

SHDesigns.