| DIY-Welder - Build your own Arc, MIG and TIG welder | Page hits: |

| DIY-Welder - Build your own Arc, MIG and TIG welder | Page hits: |

The first prototype proved the board worked and the alternator could generate enough current and voltage for welding. It took up a lot of space and the old mower was badly rusted. it would have taken a lot of work to strip down, sand prime and paint it. I wanted something more like a portable generator.

Major components:

I started with the frame from another riding mower:

|

|

The 18HP was nice, but it was huge. I opted for a 12HP engine that ran well and fits better within the frame. 1" angle iron for frame. Tank and battery sit in the top.

|

|

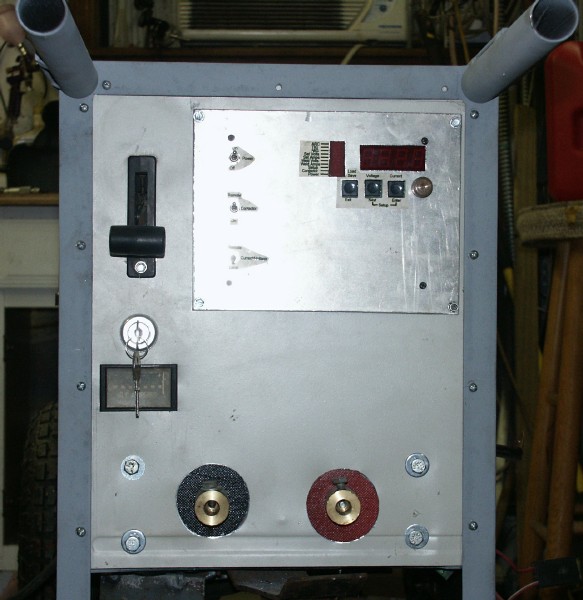

Left is the control panel and output terminals; 3/4" conduit used for handles. Right image is the pully setup underneath for the alternator. The idler in the middle makes the belt cover a longer angle around the pulleys. That helps prevent slipping. The upper idler is spring loaded.

Here's all the parts installed for an initial test. Yes, the wiring is a mess ;). There is a reactor coil at the center with 2 large capacitors. This helps smooth the arc and provides easier starting in arc mode. The caps also help it delever the large surge needed in short-arc MIG welding. Test welds show the 12HP had plenty of power for up to 3/32 rods. It should be able to do 130A on MIG.

|

|

Almost done. Side panels made out of sheet metal cut from an old clothes dryer. Just needs final top cover and paint.